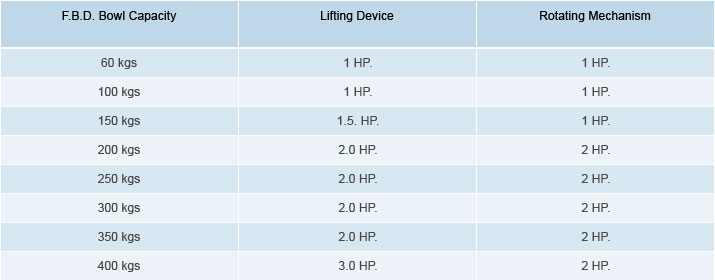

A hydraulically on mechanically operated equipment, Tipper is used for lifting and tipping FBD Bowl loaded with dried granules. Contents of the Bowl is transferred smoothly to a granulating equipment and through it to a BIN or an IPC container.

It provides completely dust free operation and eliminates tedious scooping or manual handling. The process consists of bringing the FBD Bowl beneath the Tipper. The inverted cone of the Tipper is lowered so that the brim flange of the bowl touches the brim flange of the inverted

cone. Both are then clamped together with quick fixing clamps. The whole assembly is raised Hydraulically to the required height and then rotated mechanically to 180 degree on its axis and lowered to a suitable height to align with the receiving container / equipment. The discharge point of cone is fitted with an Butterfly valve by operating which the contents are discharged to Multi Mill / Co Mill or a sifter cum Multi Mill as per the process requirement. The flanged cone and the valve is of S.S. 316 /304 material, as required. The bottom and the complete drives are covered with highly polished S.S. 304 sheets to impart a cGMP finish.