Introducing Prochem Tapasya’s cutting-edge solution: The Under Driven Cone Mill. As a leading manufacturer and supplier of industrial cone mill equipment, we specialize in providing high-quality cone milling machines tailored for pharmaceutical applications and various other industries.

Introducing Prochem Tapasya’s cutting-edge solution: The Under Driven Cone Mill. As a leading manufacturer and supplier of industrial cone mill equipment, we specialize in providing high-quality cone milling machines tailored for pharmaceutical applications and various other industries.

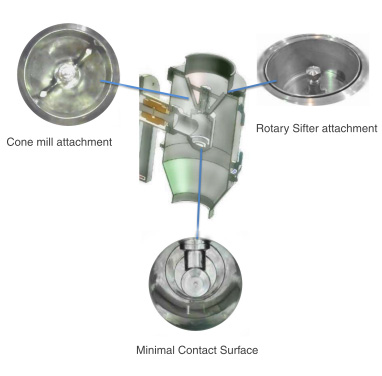

Our Pharmaceutical Under Driven Cone Mill stands out for its precision and efficiency in particle size reduction. Utilizing advanced Under Driven Cone Milling Technology, our equipment ensures consistent and uniform results, meeting the stringent requirements of pharmaceutical manufacturing.

Whether you're in pharmaceuticals or other industries requiring particle size reduction, our Custom Under Driven Cone Mill Solutions are designed to meet your specific needs. From small-scale operations to large-scale production, our cone mills deliver reliable performance and versatility.

Experience the difference with our Under Driven Cone Mill – the go-to solution for achieving superior particle size reduction efficiently and effectively. Trust in our expertise and innovation to elevate your processing capabilities.

The Under Driven Cone Mill is a versatile and indispensable piece of equipment with numerous applications across various industries.

In conclusion, the Under Driven Cone Mill's versatility, precision, and customizable nature make it indispensable across a wide range of industries for particle size reduction and milling applications. As a trusted Under Driven Cone Mill Manufacturer and Supplier, we are committed to providing High-Quality solutions that meet the diverse needs of our customers.

Choosing our Under Driven Cone Mill offers several compelling advantages that set it apart from other options in the market. Here's why you should choose our product, incorporating the provided keywords:

Choose our Under Driven Cone Mill for superior quality, performance, and support. Experience the difference with our trusted solutions tailored to your unique requirements.